Engine Core Supplier Buyers: Navigating the Automotive Remanufacturing Landscape

In the dynamic world of automotive remanufacturing, engine core suppliers play a pivotal role in ensuring the smooth flow of operations and the delivery of high-quality rebuilt engines to consumers. As key players in the automotive aftermarket industry, engine core suppliers are tasked with sourcing and buying the essential components needed to breathe new life into old engines.

Understanding the Role of Engine Core Supplier Buyers

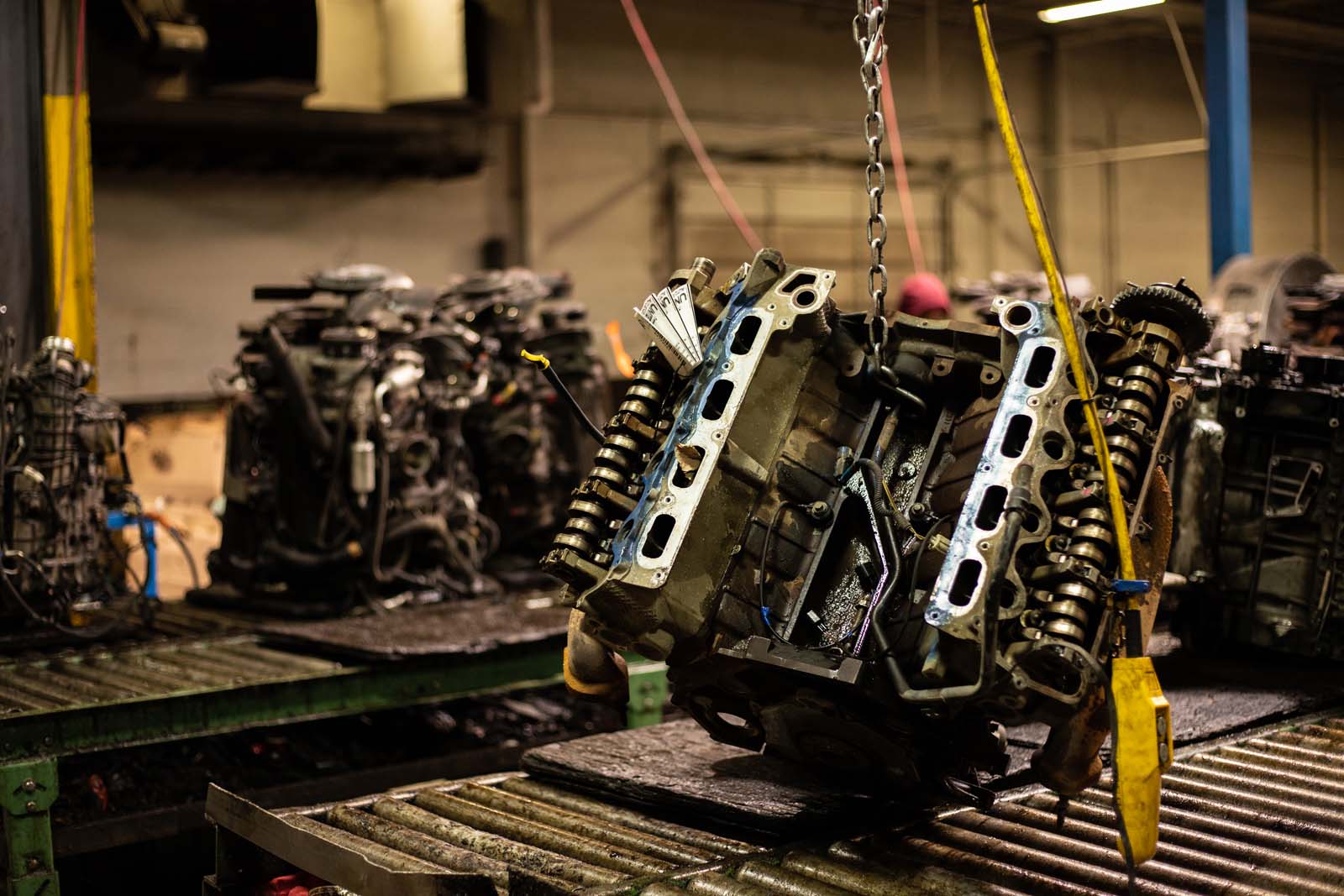

The buyers of engine cores handle obtaining the core components necessary for remanufacturing engines. These components together, often called engine cores, serve as the foundation for rebuilt engines. Engine core suppliers work closely with remanufacturers, aftermarket suppliers, salvage yards, and other industry stakeholders to source the required cores.

The process of acquiring engine cores involves careful consideration of a range of factors, including the quality, condition, and compatibility of the components. Engine core suppliers must have a deep understanding of engines, types, specifications, and market demand to make informed purchasing decisions. Maxcore’s goal, as a core supplier is to secure high-quality cores that will be remanufactured to meet original equipment manufacturer (OEM) standards.

MAXCORE

To overcome the challenges they face, engine core supplier buyers employ various strategies to streamline their procurement processes

Challenges Faced by Engine Core Supplier

Despite the importance of their role, engine core suppliers meet several challenges in their day-to-day operations. One of the primary challenges is the fluctuating availability and cost of engine cores. Factors that we mentioned, such as market demand, vehicle trends, and supply chain disruptions can significantly affect the availability and pricing of engine cores, making it challenging for buyers to secure the components they need at competitive prices.

Additionally, engine core suppliers must navigate their complex network of suppliers and salvage yards to find reliable sources of engine cores. Building and supporting relationships with trusted suppliers is crucial, but it requires time, effort, and expertise. Maxcore works hard to build and maintain relationships, ensuring the quality of their engine components.

Core suppliers must stay on top of industry trends, technological advancements, and regulatory changes that may affect the remanufacturing process. Adapting to evolving market dynamics, embracing, and creating, innovative technologies is essential for remaining competitive in the automotive remanufacturing landscape.

Strategies for Success in Engine Core Procurement

To overcome the challenges they face, engine core supplier buyers employ various strategies to streamline their procurement processes and optimize their operations. One such strategy is using data analytics and market intelligence tools to find trends, forecast demand, and track pricing fluctuations in the engine core market. By harnessing the power of data, Maxcore can make informed decisions to bring mutual benefits to both the supplier and the seller.

Building strong relationships with reputable suppliers and salvage yards is another key strategy for engine core supplier buyers. By proving trust and open communication channels with suppliers, Maxcore strives to gain access to a reliable and consistent supply of engine cores. Collaborating closely with suppliers also allows Maxcore to negotiate pricing, quality standards, and delivery schedules across the country, to best fit the needs of both the seller and core purchaser.

Engine core suppliers, like Maxcore, play a critical role in the automotive remanufacturing ecosystem, serving as the linchpin between suppliers and remanufacturers. Despite the challenges they face, engine core supplier buyers employ innovative strategies to navigate the complexities of the engine core market and ensure a steady supply of high-quality components for remanufacturing. By leveraging data analytics, fostering strong supplier relationships, and diversifying their sourcing channels, Maxcore works diligently to overcome obstacles and drive success in the ever-evolving automotive remanufacturing landscape.